The PARAMOUNT Series

10HP-400HP Electric Motor Driven Packages

“Vapor Recovery Re-imagined”

World Class Efficiency + Reliability = Value

Paramount Series applies industry leading design from the world’s 3rd largest compressor manufacturer to gas compression in the USA. Over 70,000 compressors produced every year.

Reliability: The Paramount Series utilizes the internationally patented “SKY” compressor airend. The only airend rotary screw technology design with 4 bearing on the discharge end of each airend rotor. That is two more bearings than all other gas compression brands. This bearing design extends the gas compressor airend life by over 300%.

Efficiency: The Paramount Series uses the latest rotor profiles cut on world class Kapp grinding machines in the USA. These gas compressors have proven to be 25 to 40% more efficient than every industry rotary screw gas compressor manufacturer. What does this mean? End users get 25 to 40% more gas flow (MSCFD) for the same horsepower when compared to other brands OR provides the same gas flow (MSCFD) while consuming 25 to 40% less electrical energy. That’s $15,000 to $25,000 in electrical saving annually for every 150hp Vapor Recovery Unit operated.

We manufacture 85% of the compressor components internally, ensuring quality and controlling costs.

The Paramount Series provides the strongest value in the Vapor Recovery Market and the first unit to offer a Return on Investment through industry leading longevity, reliability and energy savings!

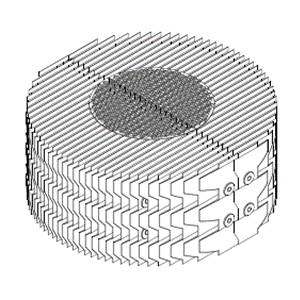

Vane Packs

- Raw combustion uses an engineered vane pack design for each application to increase the efficacy of our units.

- The vane packs a made of 304SS.

- The vane packs are removable.

- Raw combustion uses an engineered vane pack design for each application to increase the efficacy of our units.

- The vane packs a made of 304SS.

- The vane packs are removable.